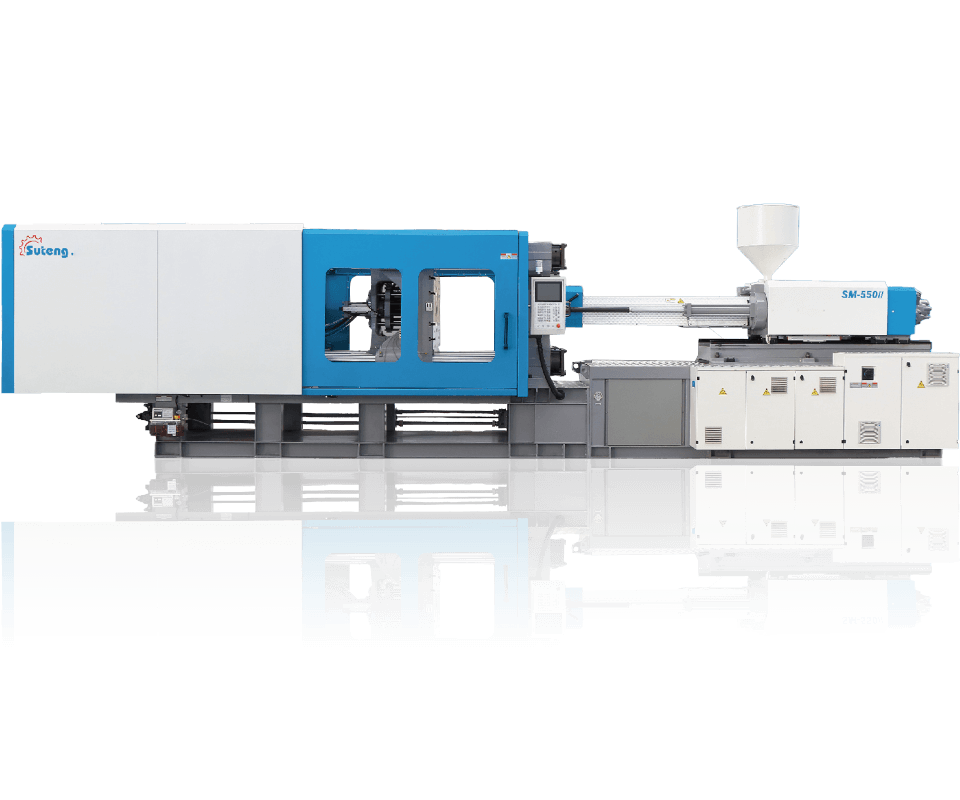

SM-II Series Plastic Injection Molding Machine

HIGH COST-PERFORMANCE

The SM-II Series Injection Molding Machine designed on the basis of advanced German &Italian technology, thus made our machines with advanced technology and extremely high cost performance.

INDIVIDUAL

Thanks to the modular design concept, customers can according to their actual needs, free combination of clamping, injection and power units, to reach to a higher performance.

HIGH REPEATABILITY PRECISION

The SM-II Series excellent injection molding performance, ensure the consistent high repeatability precise, the precision almost equal to the full-electric injection machines.

RELIABILITY

SM-II Series adopts high quality components, which ensure our machines, high performance and reliability. Save more cost for future maintenance.

- High performance dual injection cylinder structure

- High strength clamping unit

- Mechanical parts surface adopts special treatment technology

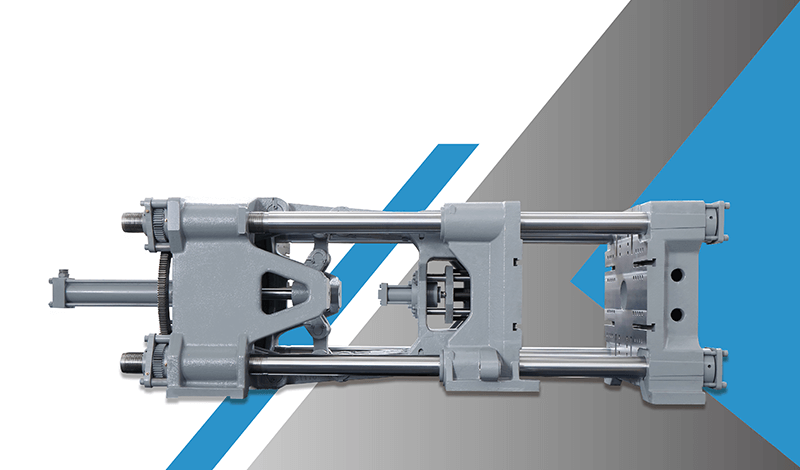

Clamping Unit

- Optimized designed mechanical structure ensure a higher strength

- Larger space between tie-bars, suitable for more molds sizes and multi-cavity products needs

- European type ejector structure, convenient for maintenance

- Graphite-copper bushes used on tie-bar and ejector, graphite-copper slider used on movable & rear platen

- Longer and wider movable platen guiding slider ensure higher repeatability precision

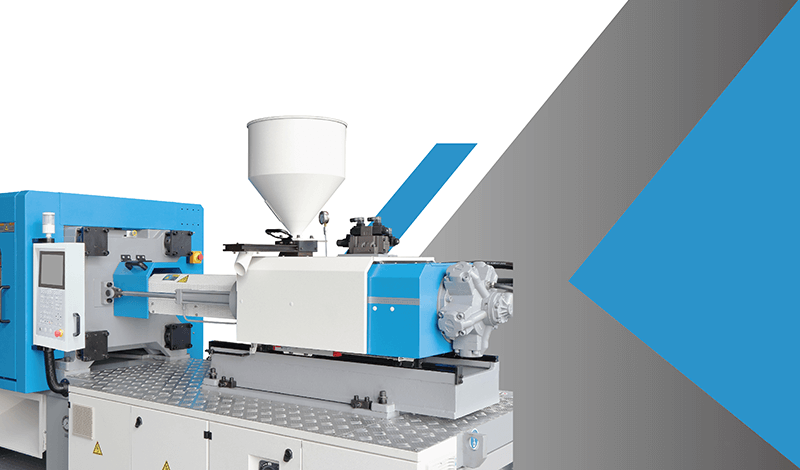

Injection Unit

- Modular designed injection structure, come true free combination of injection &clamping unit

- Dual linear guide rails coms\e with one piece type injection unit base, ensure a higher precision

- Dual carriage cylinder, improve injection precision be higher

- Injection unit hydraulic circuit adopts sleeve type connector, no welding design

- Up-turning designed nozzle cover, easier for maintenance

- Dual layer barrel cover, ensure a safer production

- Bearing type hopper slider, easier to change material and operation

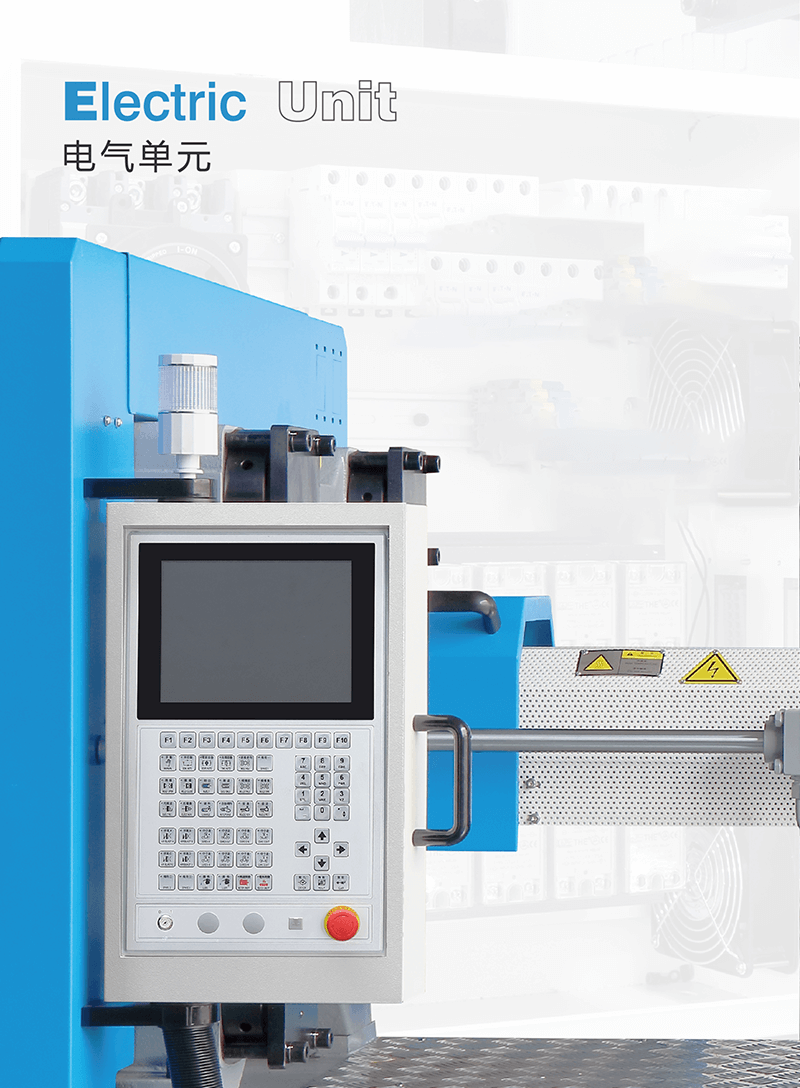

Electric Unit

- Fast response controller unit, ensure a faster and more precise control

- World-famous electric parts, reliable quality

- Three color alarm lighter with buzzer, easy to know machines, working conditions

- Heavy & light current separated distributed on our cabinet and terminal boxes

- Electric unit designed under high safety standard, ensure operation safer

- Network management function available for option

Hydraulic Unit

- Modular designed concept, upgrade & maintenance will be easier

- World-class brands hydraulic parts, ensure machines reliability and fast response

- Visible and removable designed oil tank, easy for hydraulic circuit maintenance

- DIN standard hydraulic pipe fitting with seal, G screw thread style plug, avoid oil pollution

- Self-seal suction filter, oil circuit maintenance will be easy and convenient

| INTERNA TIONAL CLASS | Unit | SM-110 II | SM-150 II | SM-180 II | SM-220 II | ||||||||

| DESCRIPTION | NO | 315 | 539 | 640 | 765 | ||||||||

| INJECTION UNIT | A | B | C | A | B | C | A | B | C | A | B | C | |

| Screw diameter | mm | 32 | 35 | 38 | 38 | 42 | 45 | 42 | 45 | 50 | 45 | 50 | 55 |

| Screw L/D ratio | L/D | 25 | 22.8 | 21 | 25 | 22.7 | 21 | 23 | 21.6 | 19.4 | 23.3 | 21 | 19 |

| Theoretical shot volume | cm2 | 137 | 164 | 193 | 227 | 277 | 318 | 311 | 357 | 441 | 398 | 490 | 593 |

| Shot weight (PS) | g | 125 | 149 | 175 | 206 | 252 | 289 | 283 | 325 | 401 | 362 | 446 | 540 |

| Injection rate | g/s | 93 | 112 | 132 | 112 | 137 | 157 | 131 | 150 | 186 | 149 | 185 | 223 |

| Injection pressure | bar | 2278 | 1904 | 1615 | 2376 | 1945 | 1695 | 2030 | 1769 | 1432 | 2038 | 1651 | 1364 |

| Max.screw speed | rpm | 220 | 220 | 185 | 185 | ||||||||

| CLAMPING UNIT | |||||||||||||

| Clamping force | kN | 1100 | 1500 | 1800 | 2200 | ||||||||

| Opening stroke | mm | 360 | 380 | 435 | 492 | ||||||||

| Distance between tie-bar | mm | 420x370 | 470x420 | 530x470 | 575x525 | ||||||||

| Max.mold height | mm | 400 | 500 | 550 | 580 | ||||||||

| Min.mold height | mm | 150 | 160 | 200 | 220 | ||||||||

| Ejector stroke | mm | 100 | 120 | 140 | 150 | ||||||||

| Ejector force | kN | 38 | 50 | 53 | 70 | ||||||||

| OTHERS | |||||||||||||

| Max.Pump pressure | MPa | 16 | 16 | 16 | 16 | ||||||||

| Pump motor power | KW | 15 | 18.7 | 23 | 26 | ||||||||

| Heating capacity | KW | 8.1 | 12.2 | 13.85 | 16.4 | ||||||||

| Machine dimensions | m | 4.25x1.17x1.6 | 4.66x1.27x1.65 | 4.95x1.34x1.7 | 5.65x1.43x1.81 | ||||||||

| Oil tank cubage | L | 200 | 250 | 250 | 300 | ||||||||

| Machine weight | t | 3.8 | 4.5 | 5.5 | 7.2 | ||||||||

※Based on the technical upgrade, the technical parameters of the product are subject to change without notice.

| INTERNA TIONAL CLASS | Unit | SM-250 II | SM-280 II | SM-350 II | ||||||

| DESCRIPTION | NO | 1010 | 1455 | 2350 | ||||||

| INJECTION UNIT | A | B | C | A | B | C | A | B | C | |

| Screw diameter | mm | 50 | 55 | 60 | 55 | 60 | 65 | 65 | 70 | 75 |

| Screw L/D ratio | L/D | 23.4 | 21 | 19.5 | 23 | 21 | 19.5 | 23.6 | 22 | 20.5 |

| Theoretical shot volume | cm3 | 471 | 570 | 678 | 665 | 792 | 929 | 1161 | 1346 | 1545 |

| Shot weight (PS) | g | 428 | 518 | 617 | 605 | 721 | 845 | 1056 | 1225 | 1406 |

| Injection rate | g/s | 185 | 224 | 266 | 181 | 215 | 253 | 306 | 355 | 407 |

| Injection pressure | bar | 2094 | 1731 | 1454 | 2139 | 1797 | 1531 | 1978 | 1705 | 1485 |

| Max.screw speed | rpm | 200 | 160 | 165 | ||||||

| CLAMPING UNIT | ||||||||||

| Clamping force | kN | 2500 | 2800 | 3500 | ||||||

| Opening stroke | mm | 492 | 560 | 675 | ||||||

| Distance between tie-bar | mm | 575x525 | 630x580 | 730x680 | ||||||

| Max.mold height | mm | 580 | 650 | 750 | ||||||

| Min.mold height | mm | 220 | 250 | 280 | ||||||

| Ejector stroke | mm | 150 | 160 | 180 | ||||||

| Ejector force | kN | 70 | 90 | 125 | ||||||

| OTHERS | ||||||||||

| Max.Pump pressure | MPa | 16 | 16 | 16 | ||||||

| Pump motor power | KW | 30 | 30 | 45 | ||||||

| Heating capacity | KW | 18.35 | 21.2 | 29.7 | ||||||

| Machine dimensions | m | 5.65x1.43x1.81 | 6.1x1.53x1.86 | 7.35x1.88x2.0 | ||||||

| Oil tank cubage | L | 300 | 400 | 500 | ||||||

| Machine weight | t | 7.5 | 9 | 12.7 | ||||||

※Based on the technical upgrade, the technical parameters of the product are subject to change without notice.

| INTERNA TIONAL CLASS | Unit | SM-450 II | SM-550 II | SM-680 II | |||||||

| DESCRIPTION | NO | 2980 | 4250 | 4935 | |||||||

| INJECTION UNIT | A | B | C | A | B | C | A | B | C | D | |

| Screw diameter | mm | 70 | 75 | 80 | 80 | 85 | 90 | 85 | 90 | 95 | 100 |

| Screw L/D ratio | L/D | 23.6 | 22 | 20.6 | 21.3 | 20 | 18.9 | 23.3 | 22 | 20.8 | 20.8 |

| Theoretical shot volume | cm3 | 1519 | 1744 | 1984 | 2215 | 2501 | 2797 | 2835 | 3179 | 3542 | 3925 |

| Shot weight (PS) | g | 1382 | 1587 | 1805 | 2016 | 2276 | 2545 | 2580 | 2893 | 3223 | 3572 |

| Injection rate | g/s | 317 | 364 | 414 | 401 | 453 | 508 | 480 | 538 | 599 | 664 |

| Injection pressure | bar | 1911 | 1664 | 1463 | 1967 | 1742 | 1554 | 2020 | 1800 | 1620 | 1450 |

| Max.screw speed | rpm | 155 | 135 | 135 | |||||||

| CLAMPING UNIT | |||||||||||

| Clamping force | kN | 4500 | 5500 | 6800 | |||||||

| Opening stroke | mm | 764 | 860 | 970 | |||||||

| Distance between tie-bar | mm | 780x730 | 880x830 | 970x920 | |||||||

| Max.mold height | mm | 780 | 850 | 980 | |||||||

| Min.mold height | mm | 300 | 350 | 380 | |||||||

| Ejector stroke | mm | 210 | 250 | 260 | |||||||

| Ejector force | kN | 125 | 150 | 207 | |||||||

| OTHERS | |||||||||||

| Max.Pump pressure | MPa | 16 | 16 | 16 | |||||||

| Pump motor power | KW | 45 | 52 | 37+37 | |||||||

| Heating capacity | KW | 32.1 | 41.5 | 44.3 | |||||||

| Machine dimensions | m | 7.48x1.9x2.1 | 8.8x2.1x2.35 | 10.1x2.3x2.7 | |||||||

| Oil tank cubage | L | 600 | 800 | 900 | |||||||

| Machine weight | t | 16.8 | 22 | 32 | |||||||

※Based on the technical upgrade, the technical parameters of the product are subject to change without notice.

| INTERNA TIONAL CLASS | Unit | SM-800 II | SM-1000 II | SM-1250 II | |||||||||

| DESCRIPTION | NO | 5610 | 6100 | 9160 | |||||||||

| INJECTION UNIT | A | B | C | D | A | B | C | D | A | B | C | D | |

| Screw diameter | mm | 90 | 100 | 110 | 120 | 90 | 100 | 110 | 115 | 110 | 115 | 120 | 125 |

| Screw L/D ratio | L/D | 24.4 | 22 | 20 | 18.3 | 25.5 | 23 | 20.9 | 20 | 23 | 22 | 21 | 20.2 |

| Theoretical shot volume | cm3 | 2990 | 3691 | 4467 | 5316 | 2988 | 3689 | 4464 | 4879 | 5270 | 5760 | 6272 | 6805 |

| Shot weight (PS) | g | 2721 | 3359 | 4065 | 4837 | 2719 | 3356 | 4062 | 4440 | 4796 | 5242 | 5707 | 6193 |

| Injection rate | g/s | 573 | 707 | 855 | 1018 | 590 | 729 | 880 | 960 | 793 | 867 | 944 | 1024 |

| Injection pressure | bar | 2190 | 1780 | 1470 | 1230 | 2160 | 1760 | 1460 | 1330 | 1860 | 1700 | 1560 | 1440 |

| Max.screw speed | rpm | 110 | 100 | 90 | |||||||||

| CLAMPING UNIT | |||||||||||||

| Clamping force | kN | 8000 | 10000 | 12500 | |||||||||

| Opening stroke | mm | 1040 | 1120 | 1320 | |||||||||

| Distance between tie-bar | mm | 1020x980 | 1080x1080 | 1250x1250 | |||||||||

| Max.mold height | mm | 1000 | 1100 | 1300 | |||||||||

| Min.mold height | mm | 400 | 450 | 550 | |||||||||

| Ejector stroke | mm | 280 | 325 | 380 | |||||||||

| Ejector force | kN | 186 | 210 | 245 | |||||||||

| OTHERS | |||||||||||||

| Max.Pump pressure | MPa | 16 | 16 | 16 | |||||||||

| Pump motor power | KW | 45+45 | 45+55 | 37+37+37 | |||||||||

| Heating capacity | KW | 50.2 | 63.9 | 74.4 | |||||||||

| Machine dimensions | m | 11x2.35x2.8 | 12.1x2.51x2.95 | 12.9x2.7x3.3 | |||||||||

| 油箱容積 | L | 1000 | 1700 | 2100 | |||||||||

| Machine weight | t | 37 | 42 | 59 | |||||||||

※Based on the technical upgrade, the technical parameters of the product are subject to change without notice.